Caps base, cover and bottles feed by vibration bowl regardless of direction. It will be arranged and commutation automatically by machine mechanism. Finished products will be checked by sensor to ensure all parts are in the right place.

The HMI touch screen displays real production data tracking, system parameters, as well as trouble shooting and parts faulty messages.

This equipment is designed for high volume production with customized product. The equipment provides high efficiency, consistency, productivity and fully automated for lateral flow diagnostic accessories products.

Key Features

Caps base, cover and bottles feed automatically with vibrator bowls

High precision peristaltic pump with adjustable volume

Liquid filled checked by high precision camera sensor

NC parts will be rejected automatically

HMI touch screen control interface

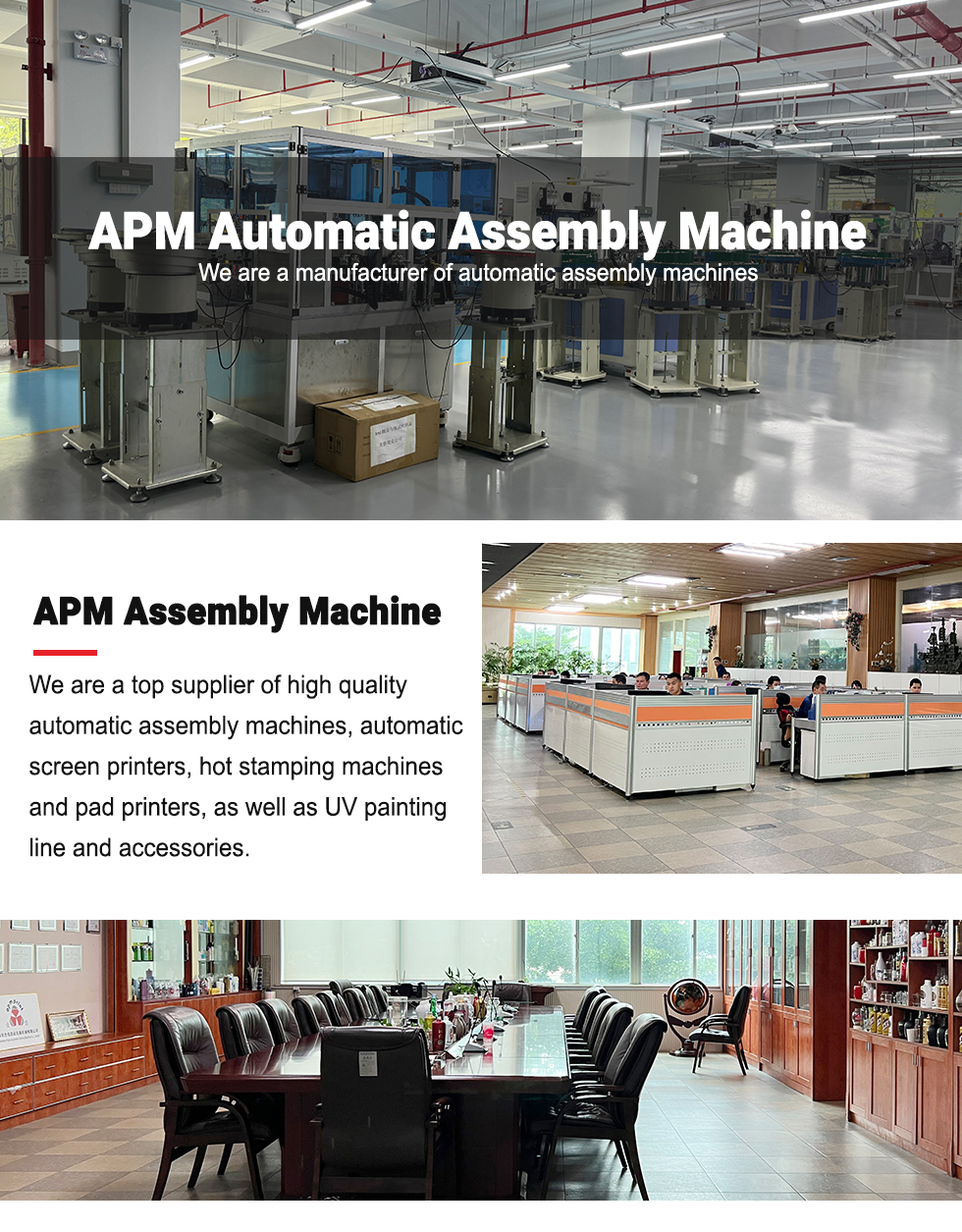

Our Factory

And we have more than 25 years of experience and hard

work in R&D and manufacturing.

APM equipment design and manufacture specialized for surgical /food/writing instruments / electricalelectronic

industries . We are committed in the Constants revest development of new products to meetever-changing social

and economic Conditions in the market

Our Certificate

All machines arekuilt in CE standard

We have customers all over the world, such as the United States, Canada, Mexico, Russia, France, Spain, Portugal,

Bulgaria, Italy, Brazil, Dominican Republic, Colombia, Australia, Algeria, Turkey, Saudi Arabia, India, Malaysia,

Vietnam, South Korea, Thailand, Kazakhstan, Uzbekistan and so on.

Production & Shipping

Project management

We provide timeline and budget study for turnkey project starting fromaterial to

the end Of the production line

On-site installation

Our service expert provides on-site installation for local and overseasclients

whenever is required

Training

We provide technical personnel training in our customer's premise

Other Application Products

| Quick Links | Hot product | Contact information |

|---|---|---|

|

|